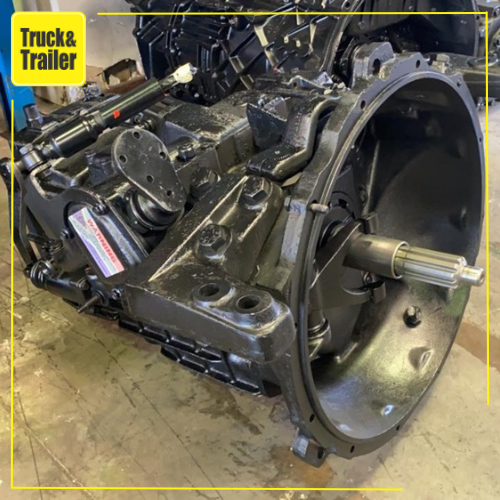

Interesting Things You Should Know About Truck Gearboxes

Date: 29/09/2022

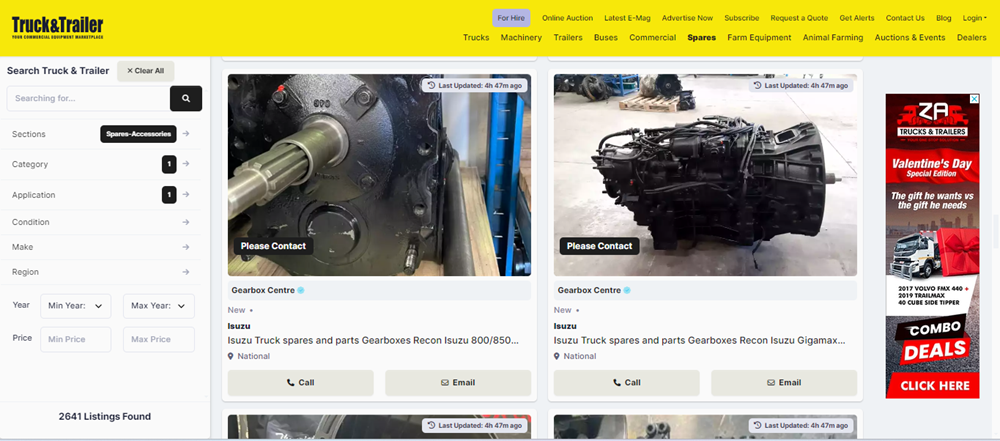

If you're a truck owner or operator, understanding the intricacies of your vehicle's gearbox is crucial to ensuring optimal performance and longevity. Truck gearboxes play a significant role in the overall functionality and efficiency of your vehicle, so taking the time to learn about them is essential. Let's now delve into the vital aspects of truck transmissions, shedding light on their types, functions, maintenance, and significance in South Africa's bustling logistics industry. Find the right spares for your commercial equipment on Truck & Trailer. Visit us today to avoid disappointment.

Types of Truck Transmissions:

Truck transmissions come in various configurations, each suited to different applications and performance requirements. In South Africa, the most common types include manual, automatic, and automated manual transmissions (AMTs).

Manual Transmission: Manual gearboxes require the driver to manually shift gears using a clutch pedal and gear shifter. While they offer better control over the vehicle's speed and performance, they can be more challenging to operate for some drivers.

Automatic Transmission: Automatic gearboxes, on the other hand, shift gears automatically without the need for manual intervention. They are easier to operate, making them a popular choice for drivers who prefer a more convenient driving experience.

Automated Manual Transmission (AMT): AMT systems combine the convenience of automatic transmissions with the efficiency of manual transmissions. They use computer-controlled actuators to shift gears, providing a smooth and efficient driving experience.

Importance in South Africa's Logistics Industry:

In a country as vast and diverse as South Africa, efficient transportation is essential for economic growth and development. Truck gearboxes play a pivotal role in ensuring the smooth flow of goods across the nation's extensive road network. Whether traversing the arid landscapes of the Karoo or navigating the bustling highways of Gauteng, reliable gearboxes are indispensable for maintaining schedules and meeting delivery deadlines. Moreover, with the rise of e-commerce and just-in-time inventory systems, the demand for efficient logistics solutions has never been higher, underscoring the critical role of truck gearboxes in driving productivity and competitiveness.

Maintenance and Care:

Proper maintenance is crucial for prolonging the lifespan of truck gearboxes and ensuring optimal performance. Regular inspections, fluid checks, and lubrication are essential to prevent wear and tear, minimise downtime, and avoid costly repairs. Fleet managers should implement comprehensive maintenance schedules and provide training to drivers on best practices for gearbox care. Additionally, prompt addressing of any unusual noises, vibrations, or gear shifting issues can help preempt potential breakdowns and keep operations running smoothly.

Read: Essential Truck Transmission Maintenance and Repairs

Challenges and Solutions:

Despite their robustness, the gearboxes are not immune to challenges, especially in the demanding operating conditions encountered in South Africa. Extreme temperatures, rough terrain, and heavy loads can exert significant stress on transmission components, leading to premature failure if not adequately addressed. To mitigate these challenges, manufacturers are continually innovating with advanced materials, lubricants, and cooling systems to enhance durability and reliability. Furthermore, advancements in telematics and predictive maintenance technologies empower fleet operators to monitor gearbox health in real-time, enabling proactive interventions and minimising disruptions.

Exploring Gearbox Customisation:

In addition to standard gearbox configurations, South Africa's trucking industry has seen a rise in customised solutions tailored to specific operational needs. From heavy-duty mining applications to urban delivery fleets, manufacturers and aftermarket specialists offer a range of options to optimise gearbox performance. Custom gear ratios, differential locks, and off-road packages are just some of the modifications available to enhance traction, torque delivery, and overall efficiency in diverse operating conditions. This trend towards customisation reflects the industry's commitment to maximising productivity while minimising environmental impact, showcasing the ingenuity and adaptability of South Africa's trucking ecosystem.

The Role of Driver Training and Education:

While advancements in gearbox technology have undoubtedly improved performance and efficiency, the human element remains integral to optimising gearbox operation. Comprehensive driver training and education programs play a crucial role in ensuring that operators fully understand the capabilities and limitations of their vehicle's gearbox. From efficient shifting techniques to understanding gearbox diagnostics, knowledgeable drivers are better equipped to make informed decisions on the road, contributing to safer, more efficient transport operations. In our country, initiatives aimed at enhancing driver skills and promoting best practices in gearbox management are essential for elevating standards across the industry and reducing accidents and downtime.

Sustainable Gearbox Solutions:

As global concerns about climate change and environmental sustainability continue to grow, the trucking industry is increasingly focused on adopting greener technologies and practices. Gearbox manufacturers are responding to this demand by developing eco-friendly solutions that reduce emissions and minimise environmental impact. Hybrid and electric drivetrains, coupled with regenerative braking systems, are revolutionising the way trucks operate, offering quieter, cleaner alternatives to traditional diesel-powered vehicles. By embracing sustainable gearbox solutions, the trucking sector is not only reducing its carbon footprint but also future-proofing its operations against evolving regulatory pressures and consumer preferences.

The Impact of Digitalisation and Connectivity:

The digital revolution is reshaping every aspect of the trucking industry, including gearbox management and maintenance. Connected vehicles equipped with onboard sensors and telematics systems provide real-time data on gearbox performance, allowing fleet managers to monitor health indicators, detect potential issues, and schedule maintenance proactively. Predictive analytics algorithms can forecast gearbox failures based on historical data and usage patterns, enabling preemptive action to prevent costly breakdowns and minimise downtime. Furthermore, remote diagnostics and over-the-air software updates streamline servicing processes, reducing the need for manual intervention and optimising fleet efficiency. In South Africa, where vast distances and remote locations pose logistical challenges, digitalisation is proving to be a game-changer in optimising gearbox performance and ensuring uninterrupted operations.

Looking Ahead:

As the trucking industry continues to evolve, driven by technological innovation, regulatory changes, and shifting consumer expectations, the role of truck gearboxes will remain pivotal in shaping the future of transportation. From rugged mining haulers to sleek urban delivery vans, the diversity of applications and operating conditions demands versatile, reliable gearbox solutions that can adapt to the demands of the modern marketplace. By embracing customisation, sustainability, and digitalisation, stakeholders can unlock new opportunities for growth, efficiency, and environmental stewardship, ensuring that South Africa's trucking sector remains at the forefront of innovation and excellence for years to come. So, as we embark on this journey towards a brighter, more sustainable future, let us remember that the gearbox is not just a mechanical component but a symbol of resilience, progress, and ingenuity in motion.

Overall, understanding the importance of the gearbox in your truck is essential for safe and efficient driving. By knowing the basics of truck gearboxes, maintaining your gearbox properly, and choosing the right gearbox for your needs, you can unlock the power of your truck and enjoy a smooth and reliable driving experience. Visit Truck & Trailer to get the appropriate spares for your commercial machinery. To avoid disappointment, come see us today.