How to Choose: Mechanical Fuel Pump vs Electrical Fuel Pump

Date: 27/09/2022

Your fuel pump is one of the most critical components your vehicle uses to deliver fuel to its engine. It has to work properly to ensure that the truck's engine runs smoothly. In most modern trucks, there are two kinds of fuel pumps: mechanical and electrical. In this article, we’ll take a look at mechanical versus electrical fuel pumps and share tips on how to choose the correct one.

Browse through Truck & Trailer for a wide range of truck spares and accessories.

The Difference Between Mechanical and Electrical Fuel Pump

While it's common to say that a fuel pump is either mechanically actuated or electrically powered, let’s go beyond that when it comes to making comparisons. Today we will look at a comparison and understand what each entails.

Mechanical fuel pump

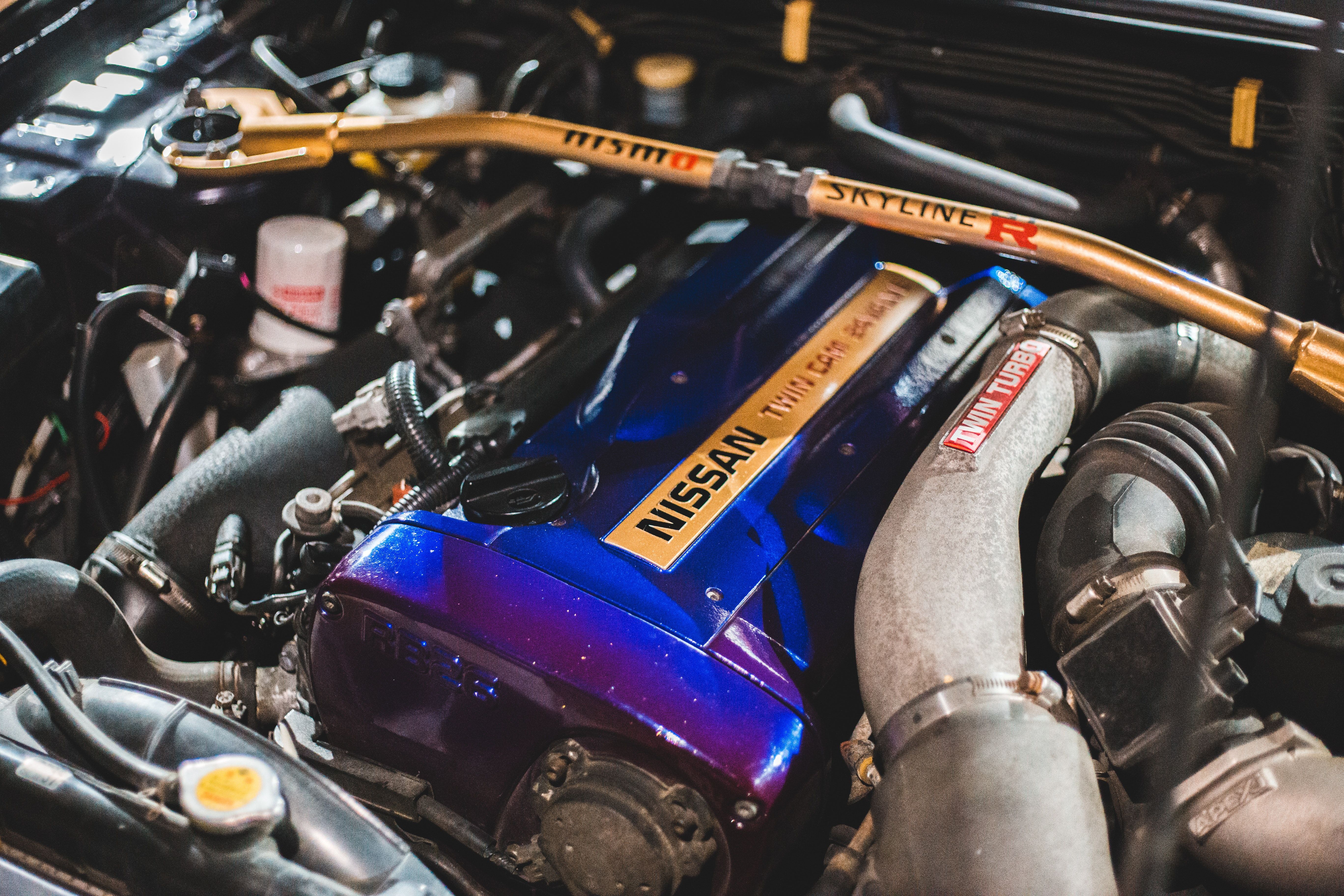

A mechanical fuel pump is an integral part of an automobile's engine, and it's typically placed on top of the combustion chamber. This type of vacuum delivers the fuel to the engine. If you're driving a car that's carburetted or a specialty, you might notice that it has a mechanical fuel pump.

A mechanical fuel pump is actuated by a lever that's located on either a Cam lobe or a fuel pump eccentric. Other types of fuel pumps, such as those made by the BBC, use a pushrod between the cylinder and the pump.

The lever creates a suction that pulls the fuel from the tank and then delivers it to the carburettor, which is usually a two- or four-barrel model. Additionally, mechanical fuel pumps come with a pre-set fuel pressure, which works with the most common two- and four-barrel carburettors. Although mechanical fuel pumps do not require a fuel-return line, some vehicles with older models may have one.

A mechanical fuel pump is generally quiet when it's pumping and cannot be heard when the engine is running. This is why it's important to thoroughly test them with a vacuum and fuel-pump tester.

Unfortunately, a mechanical fuel pump can't provide enough volume and pressure to allow fuel-injection conversions. This is especially true for vehicles that use an EFI surge tank, such as those from FiTech and Edelbrock. Also, since they don't pump fuel unless the engine is running, it can take an extended period of time to start a truck.

If your vehicle's battery is marginal, it could potentially lead to a dead battery before you can start the engine. You can also get a battery tender if you don't already have one.

Electrical fuel pump

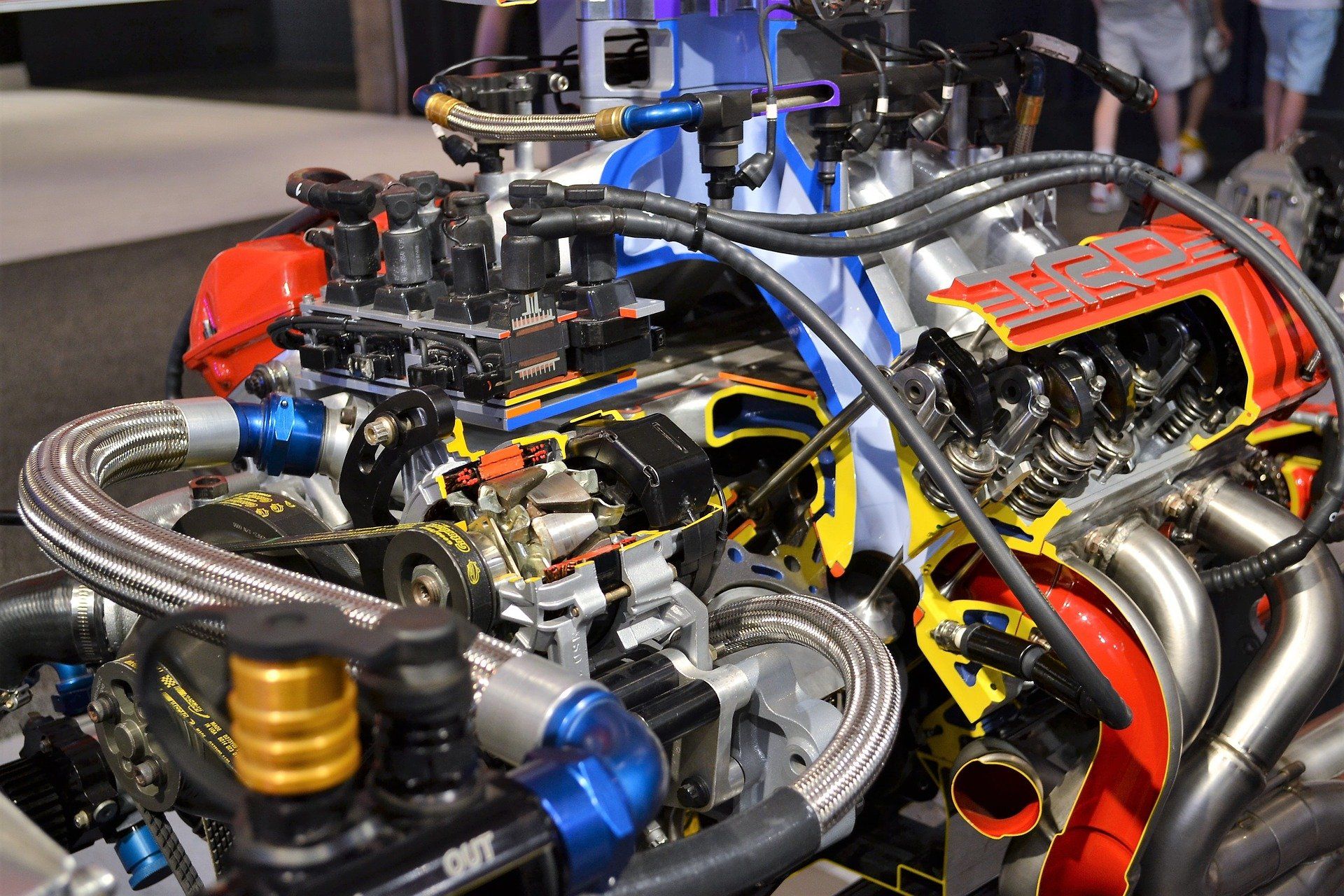

There are various types of electric fuel pumps that can be used for both fuel-injected and carburetted applications. These include fuel pump models that are universal and can be mounted on either the frame rail or the body. They can also be used inside the fuel tank or fuel cell.

Unlike the traditional fuel pump, which ‘sucks’ the fuel out of the tank, an electric fuel pump actually pushes the fuel into the engine. This means that the pump should be mounted as close to the tank as possible to prevent starvation and burn-up. An external electric fuel pump kit can also be used to nourish the pump.

Without the fuel flowing through the pump, the electric motor will lose power and stall. This is why it's important that the pump be mounted as close to the tank as possible. In addition to preventing starvation and burn-up, mounting the pump can also help keep it working properly.

Most electric fuel pumps will require a return or bypass style regulator to allow them to operate properly at the higher pressures. This is especially important for fuel injection. Although a dead head regulator can be used for most applications, it is typically not enough to prevent a fuel pressure ‘creep’. This is why we highly suggest using a bypass regulator for those setups.

What are their common issues?

The common issue of mechanical fuel pumps is that they are prone to experiencing various challenges such as the leakage of fuel into the crankcase. These could be from a faulty diaphragm spring, a vapour lock in the pump, and a fuel pressure drop.

However, when an electric fuel pump fails, it can be caused by various factors such as dirt and rust buildup on the fuel tank, low fuel level, improper pressure gauge, and wiring problems. Besides these, other issues such as loss of power and whining noises can also occur when the pump fails.

Here are Helpful Facts to Help You Choose The Right Fuel Pump

When it comes to determining how much fuel is required to support a certain type of engine, the amount of horsepower it has determines the amount of fuel it will need. As its power increases, so does the volume of fuel that it will need to carry out its operation. A good estimate of how much fuel it will require to power a given engine is around 10 hp per gallon or around 2.64 hp per litre. However, to determine the gph of your engine, you must also take into account the fuel pressure required. Different engines require different fuel pressure. So, before you buy a new fuel pump, it's important to know the maximum pressure that your engine will need. This is because the amount of flow that a pump can produce depends on its pressure.

Although there are many advantages and disadvantages to consider when choosing between an electric or mechanical fuel pump, it’s important to consider the practicality of the product. Are you looking for affordable truck spares, parts, and fuel system? Visit Truck & Trailer today to find the fuel system and parts you need.