Soil compaction: Why it is important in construction?

Date: 11/08/2022

Soil compaction is an integral part of the construction industry. Whether you’re building a pavement or foundations for a structure, you’ll need to implement this process. If you don’t compact the soil properly, it later puts your construction project at risk. Need durable soil compaction equipment? Find what you’re looking for on Truck & Trailer.

Why is soil compaction important?

Soil compaction is essential because it provides a flat base for different types of construction jobs. You’ll need to prepare the soil before constructing:

- Buildings

- Foundations

- Highway embankments

- Pavements

- Earth dams

- Roads

Compaction provides stability and support to the structures that are built on top of it. This process increases the resilience of the soil. Attention to detail is required as it’s important to ensure that the structure is supported properly. When building starts, the soil is often disrupted, causing water and air to be introduced into it. The soil compaction process removes this water and air to create a solid foundation.

Soil compaction improves the strength of the soil and reduces its compressibility. The soil’s permeability is also lowered as it’s more difficult for water to flow through it when the spaces between the particles are decreased. As a result of this process, the soil can hold more weight and its durability is enhanced. Its resistance to damage from frost or deformation is also increased.

What are the risks of not compacting the soil?

If the soil isn’t compacted properly, it’s a recipe for disaster later. Over time the soil may move suddenly, and water may pass underneath the surface of the foundation. This movement can cause damage to the walls of buildings and they could even collapse. Without proper soil compaction during construction, roads can become unstable and the pipes underneath them could crack.

What are the different types of soil compaction?

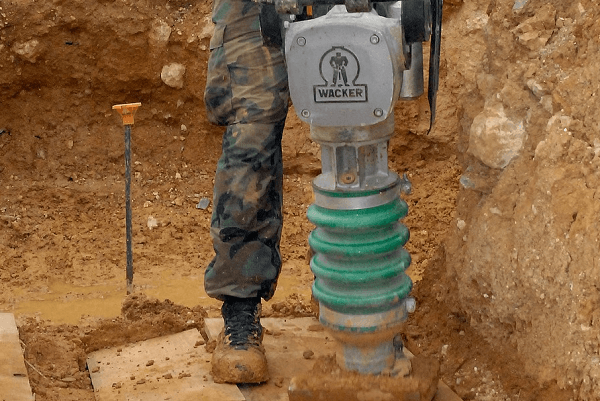

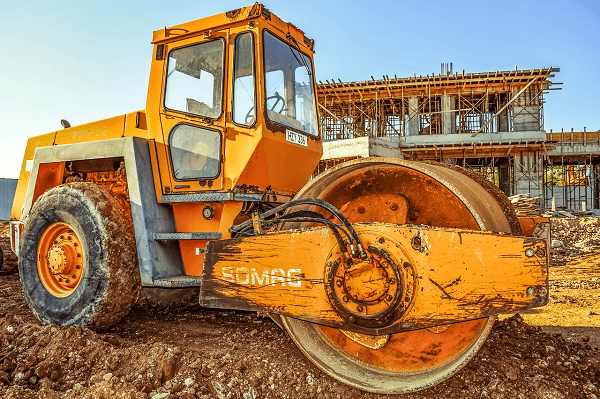

There are four different techniques that are used to achieve the desired result. Vibration, impact, needing and pressure can all be used for this process. Either static or vibratory force is used to get the job done. While static force relies on the weight of the machine to compress the soil, vibratory methods use mechanically driven force to achieve this effect.

Kneading and pressure are static types of compaction that are well-suited to working with the topsoil layers. When the deeper layers of the soil need to be compacted, vibratory methods are best. These machines apply fast impacts to the soil.

What are the different soil types?

The machine you use will depend on the type of soil you’re working with, as well as the conditions. The different types of soil vary in density and moisture content. Grain sizes determine which category the soil falls into. Soil types include the following:

- Cohesive – Soil particles stick together, making high-impact compaction the best choice. Clay can be categorised as a cohesive soil.

- Granular – Soil particles range in size. This type of soil offers good drainage. Shaking or vibratory compaction is well-suited to this type of soil. Sand and gravel are classified as granular.

- Granular and cohesive – A combination of both types of soil makes more accurate compaction necessary. The most prevalent types of soil will determine which equipment is most suitable.

What equipment do you need?

Investing in robust soil compaction equipment helps to boost the efficiency of your construction business. Consider your budget and the types of projects that you typically work on before deciding. The type of soil, as well as its moisture content, determines which machines are best to use. The following types of soil compaction equipment are available:

- Plate compactors

- Sheepsfoot compactors

- Smooth wheel rollers

- Vibratory rollers

- Pneumatic tyred rollers

- Trench rollers

- Reversible plate compactors

- Tow behind compactors

- Forward plate compactors

- Grid rollers

Now that you know the importance of soil compaction, make sure you invest in high-quality equipment. You can find a compactor for sale on Truck & Trailer.