Types of Hydraulic Parts in Industrial Machinery

Date: 29/09/2023

Hydraulic systems play a pivotal role in powering various types of industrial machinery, facilitating smooth and efficient operation across multiple sectors. Understanding the different types of hydraulic parts is essential for ensuring optimal performance and maintenance of these vital systems. In this article, we delve into the various components that make up hydraulic systems in industrial machinery, highlighting their functions and importance. Take a moment to explore all listed machinery spares available on Truck & Trailer to expand and enhance your business.

Types of Hydraulic Parts in Industrial Machinery

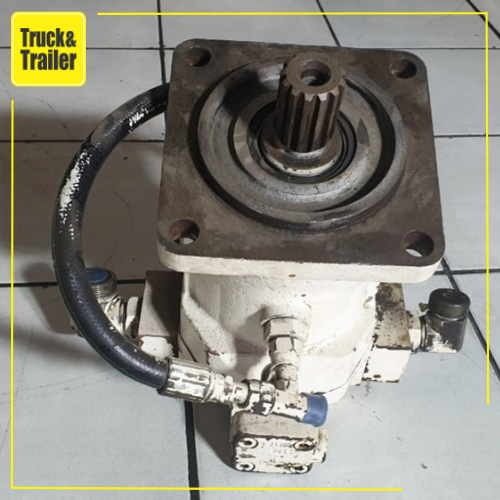

- Hydraulic Pump:

The heart of any hydraulic system, the pump converts mechanical energy into hydraulic energy by pressurising the hydraulic fluid. Types include gear pumps, vane pumps, and piston pumps, each offering unique advantages in terms of efficiency and pressure capabilities.

- Hydraulic Cylinder:

Cylindrical devices that convert fluid power into linear mechanical force and motion. Common types include single-acting cylinders, double-acting cylinders, and telescopic cylinders, catering to diverse industrial applications.

- Hydraulic Valve:

Control the flow and direction of hydraulic fluid within the system. Varieties include directional control valves, pressure control valves, and flow control valves, allowing precise regulation of hydraulic functions.

- Hydraulic Motor:

Converts hydraulic energy into mechanical energy to drive machinery. Types range from gear motors to vane motors, providing rotational motion for various industrial processes.

- Hydraulic Hose:

Flexible tubing that carries hydraulic fluid between components. Constructed from durable materials to withstand high pressures and harsh operating conditions, ensuring reliable fluid transfer.

- Hydraulic Filter:

Essential for maintaining the cleanliness of hydraulic fluid by removing contaminants. Filters prevent damage to hydraulic components and extend the lifespan of the system, promoting efficient operation.

- Accumulator:

Stores hydraulic energy to supplement pump flow during peak demand. Types include bladder accumulators, piston accumulators, and diaphragm accumulators, providing energy storage solutions for hydraulic systems.

- Hydraulic Reservoir:

Stores hydraulic fluid and facilitates air separation and cooling. Reservoirs come in various shapes and sizes, designed to accommodate specific machinery requirements and operating environments.

Some interesting aspects of these hydraulic parts

Hydraulic Pump Efficiency: While all hydraulic pumps serve the same fundamental purpose of converting mechanical energy into hydraulic energy, advancements in pump technology have led to significant improvements in efficiency. For instance, axial piston pumps feature swashplate designs that optimise fluid flow, resulting in higher efficiency and reduced energy consumption compared to traditional gear pumps.

Innovative Hydraulic Cylinder Designs: Modern hydraulic cylinders often incorporate innovative design features to enhance performance and durability. For example, some cylinders utilise composite materials in their construction, offering benefits such as reduced weight, improved corrosion resistance, and enhanced fatigue strength. Additionally, advanced sealing technologies, such as polyurethane and elastomer seals, help minimize leakage and extend the service life of hydraulic cylinders in demanding industrial applications.

Valve Control Systems: The evolution of hydraulic valve control systems has revolutionised industrial machinery operations. Integrated electronic valve control (EVC) systems enable precise adjustment of flow rates and pressure levels, allowing for fine-tuning of machine performance to meet specific production requirements. Furthermore, proportional valves equipped with feedback sensors provide real-time data on system parameters, facilitating adaptive control strategies for optimal efficiency and performance.

Hydraulic Motor Applications: Hydraulic motors find applications in a wide range of industrial machinery, from construction equipment to agricultural machinery and manufacturing systems. One fascinating application is in renewable energy technology, where hydraulic motors drive hydraulic pumps to convert wave or tidal energy into electrical power. This innovative approach harnesses the natural movement of water to generate clean and sustainable energy.

Advancements in Hydraulic Hose Technology: The development of high-performance hydraulic hoses has been driven by the demand for greater durability and reliability in harsh operating conditions. Innovative materials, such as thermoplastic elastomers and synthetic rubber compounds, offer superior resistance to abrasion, chemicals, and extreme temperatures, ensuring uninterrupted fluid transfer in critical industrial processes. Moreover, the integration of diagnostic technologies, such as RFID tags and embedded sensors, enables real-time monitoring of hose condition and performance, enhancing maintenance practices and minimising downtime.

The Role of Filtration in Hydraulic Systems: Filtration is a critical aspect of hydraulic system maintenance, as it helps preserve the integrity of hydraulic fluid and protect sensitive components from damage. Advancements in filtration technology have led to the development of high-efficiency filter media capable of capturing particles as small as a fraction of a micron. Additionally, smart filtration systems equipped with predictive maintenance algorithms can anticipate filter clogging and schedule replacement proactively, optimising system reliability and reducing operational costs.

Innovative Designs in Hydraulic Accumulators: Traditional hydraulic accumulators have undergone innovative redesigns to improve efficiency and performance. For example, hybrid hydraulic accumulators combine the benefits of gas and liquid storage systems, offering higher energy density and faster response times compared to conventional designs. Furthermore, the integration of advanced materials, such as carbon fiber-reinforced composites, enhances the strength-to-weight ratio of accumulators, making them ideal for weight-sensitive applications in aerospace and automotive industries.

Hydraulic Reservoir Optimisation: The design and placement of hydraulic reservoirs have a significant impact on system performance and reliability. Integrating features such as baffles and internal partitions helps reduce fluid turbulence and improve air separation, ensuring consistent fluid flow and pressure regulation. Moreover, the incorporation of cooling elements, such as heat exchangers or fins, enhances thermal management and prevents overheating of hydraulic fluid, especially in high-temperature environments or heavy-duty applications.

In summary, understanding the diverse types of hydraulic parts is crucial for maximising the performance and longevity of industrial machinery. From pumps and cylinders to valves and hoses, each component plays a vital role in powering hydraulic systems efficiently. By selecting the right components and ensuring regular maintenance, businesses can optimise the operation of their machinery, enhancing productivity and minimising downtime. Embracing the advancements in hydraulic technology and investing in high-quality components are key steps towards achieving seamless operations in industrial settings. Explore all listed machinery spares available on Truck & Trailer to expand and enhance your business.