Understanding Brake Systems for Trucks: Ensuring Safety on the Roads

Date: 27/01/2023

Brake systems for trucks play a pivotal role in ensuring safety on the roads. As heavy-duty vehicles navigate diverse terrains and transport vital goods across the country, reliable braking mechanisms are essential to prevent accidents and maintain operational efficiency. This article explores the basics of truck brake systems in South Africa, focusing on their components, functionality, and importance in promoting road safety. Start searching for truck accessories for sale on Truck & Trailer now.

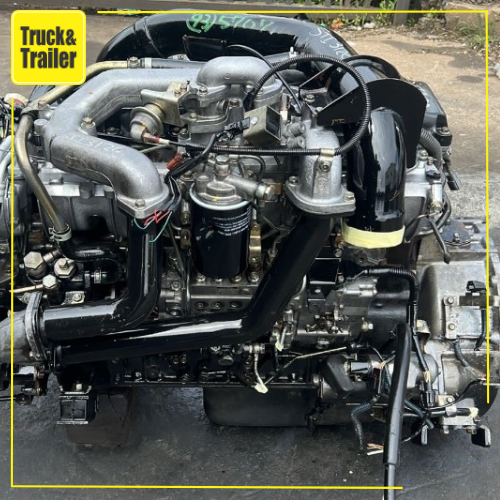

What Are Brake Systems for Trucks?

These are complex mechanisms that are designed to slow down or stop the vehicle when the driver applies pressure to the brake pedal. The main components of a truck's brake system include brake pads, rotors, calipers, brake lines, brake fluid, and the master cylinder. When the driver presses the brake pedal, hydraulic pressure is created, which forces the brake pads to press against the rotors, creating friction and slowing down the vehicle.

Types of Brake Systems for Trucks

There are two main types of brake systems used in trucks: drum brakes and disc brakes. Drum brakes are commonly found in older trucks and consist of brake shoes that press against the inside of a rotating drum to slow down the vehicle. Disc brakes, on the other hand, are more commonly used in modern trucks and feature brake pads that press against a rotating disc to create friction and stop the vehicle.

Importance of Maintaining Brake Systems

Proper maintenance of a truck's brake system is essential to ensure its optimal performance and to prevent accidents on the road. Regular inspections and servicing of the brake system can help identify any potential issues or wear and tear that may affect its effectiveness. It is crucial to check the brake pads, rotors, brake lines, and brake fluid regularly to ensure that they are in good condition and functioning correctly.

Common Signs of Brake System Problems

It is essential for truck drivers to be aware of the common signs of brake system problems to prevent accidents and ensure their safety on the road. Some of the common signs of brake system issues include squeaking or grinding noises when braking, longer stopping distances, a spongy brake pedal, and a vibrating steering wheel when applying the brakes. If any of these signs are present, it is crucial to have the brake system inspected and repaired by a qualified mechanic immediately.

Components of Brake Systems for Trucks

Brake systems for trucks consist of various components working cohesively to facilitate efficient braking. These components include:

Brake Pads: These are friction materials pressed against the brake rotors to create the necessary friction for slowing down or stopping the vehicle.

Brake Rotors: Also known as brake discs, these rotating components are mounted on the wheels and work in conjunction with the brake pads to generate friction and halt the vehicle's movement.

Brake Calipers: These are hydraulic or mechanical devices housing the brake pads and exerting pressure on them to clamp down on the brake rotors, thereby slowing or stopping the wheels' rotation.

Brake Lines: These are conduits that transport brake fluid from the master cylinder to the brake calipers, enabling the hydraulic system to exert pressure on the brake pads.

Master Cylinder: This component converts the pressure applied to the brake pedal by the driver into hydraulic pressure, which is transmitted through the brake lines to engage the brake calipers.

Brake Fluid: A specialised hydraulic fluid that transfers force from the master cylinder to the brake calipers, facilitating smooth and responsive braking action.

Functioning of Brake Systems

When a truck driver depresses the brake pedal, it initiates a series of actions within the brake system. The master cylinder converts the applied force into hydraulic pressure, which is transmitted through the brake lines to the brake calipers. The calipers then squeeze the brake pads against the rotating brake rotors, generating friction that slows down or halts the vehicle's movement. This process is repeated each time the brakes are engaged, providing reliable stopping power to the truck.

Significance in Enhancing Road Safety

Truck’s brake system are integral to ensuring road safety. Heavy-duty vehicles require robust braking mechanisms to effectively stop or slow down, especially when carrying substantial loads or navigating challenging terrain. Well-maintained brake systems contribute to:

Accident Prevention: Properly functioning brake systems enable drivers to respond promptly to potential hazards on the road, reducing the risk of collisions and accidents.

Control and Stability: Effective braking enhances the truck's control and stability, particularly during emergency maneuvers or adverse weather conditions, minimising the likelihood of skidding or loss of control.

Compliance with Regulations: South Africa has stringent regulations governing vehicle safety, including brake performance standards. Trucks equipped with reliable brake systems are more likely to comply with these regulations, avoiding penalties and ensuring operational legality.

Protection of Cargo and Infrastructure: By facilitating controlled deceleration and stopping, brake systems help protect the truck's cargo from damage and prevent undue strain on roads, bridges, and other infrastructure.

Challenges and Innovations

Despite the critical role of brake systems for trucks, challenges persist, particularly in the context of South Africa's transportation landscape. Factors such as inadequate maintenance practices, harsh operating conditions, and driver behavior can compromise brake performance and safety. To address these challenges, the industry is witnessing continuous innovations aimed at enhancing brake system reliability and effectiveness.

1. Maintenance Education: Educating truck drivers and fleet operators about the importance of regular brake maintenance is essential. Training programs and workshops can raise awareness about proper inspection procedures, early warning signs of brake system issues, and the significance of timely repairs.

2. Advanced Brake Technologies: Innovations in brake technology, such as electronic braking systems (EBS) and anti-lock braking systems (ABS), are increasingly being integrated into trucks to improve braking performance and control. These systems enhance stability and prevent wheel lock-up during braking, especially on slippery surfaces.

3. Brake Monitoring Systems: Real-time monitoring systems equipped with sensors and telematics capabilities enable remote monitoring of brake performance and condition. Fleet managers can receive alerts for potential issues, allowing for proactive maintenance and minimising downtime.

4. Enhanced Material and Design: Manufacturers are continuously developing brake pads, rotors, and calipers using advanced materials and designs to improve durability, heat dissipation, and overall performance. These innovations result in longer service life and reduced maintenance costs for truck operators.

5. Regulatory Compliance: Stricter enforcement of safety regulations pertaining to brake performance and maintenance is essential to ensure accountability across the industry. Regular inspections and compliance audits can help identify non-compliant vehicles and encourage adherence to safety standards.

Future Outlook

Looking ahead, the future of truck's brake systems is poised for further advancements driven by technological innovation and regulatory evolution. As the industry strives for higher safety standards and operational efficiency, continued collaboration between stakeholders – including manufacturers, regulators, fleet operators, and drivers – will be crucial.

Investments in research and development will lead to the emergence of even more sophisticated braking technologies, capable of addressing evolving challenges such as autonomous driving and electrification. Moreover, increased emphasis on sustainability may drive the adoption of eco-friendly braking solutions with reduced environmental impact.

In this dynamic landscape, proactive maintenance practices and ongoing skills development will remain paramount to ensure the optimal performance of brake systems and uphold road safety standards. By embracing innovation, fostering collaboration, and prioritising safety, the trucking industry can pave the way for a safer, more efficient future on the roads.

FAQs

1. How often should I have my truck's brake system checked?

It is recommended to have your vehicle's brake system checked at least once a year or more frequently if you notice any signs of brake system problems.

2. Can I replace the brake pads on my truck myself?

While it is possible to replace the brake pads on your truck yourself, it is recommended to have a qualified mechanic do the job to ensure the proper installation and functioning of the brake system.

3. What should I do if my truck's brake pedal feels spongy?

If your truck's brake pedal feels spongy, it is essential to have the brake system inspected by a mechanic immediately to identify and address any underlying issues.

4. How can I extend the lifespan of my truck's brake system?

Regular maintenance, including checking brake pads, rotors, and brake fluid, can help extend the lifespan of your truck's brake system and ensure its optimal performance.

5. Are drum brakes or disc brakes better for trucks?

Disc brakes are generally considered to be more efficient and provide better stopping power than drum brakes, making them a preferred choice for modern trucks.

Overall, brake systems for trucks are not merely mechanical components but vital safety features that safeguard lives, protect cargo, and uphold operational integrity on the roads. Understanding the complexities of these systems and embracing innovations are essential steps toward achieving higher levels of safety and efficiency in the transportation sector. With concerted efforts from all stakeholders, including regulatory bodies, manufacturers, fleet operators, and drivers, the vision of safer roads and smoother journeys can be realised, ensuring a brighter future for trucking in South Africa. Go to Truck & Trailer and start looking for truck accessories.